Impact-Resistant Gloves: What the Ratings Mean

When having any discussion on personal protective equipment (PPE), it must begin with your PPE risk assessment. You know the drill – identify the risks or hazards that are present in work areas or for assigned tasks and follow the hierarchy of controls to eliminate the hazards or reduce their exposures.

Addressing compliance needs, the Occupational Safety and Health Administration (OSHA) has established requirements for employers to conduct PPE risk assessments (1910.132; 1926.28). Beyond compliance, it just makes good business sense to know the hazards employees face and to prevent or reduce exposures to eliminate and reduce employee injuries.

One area to address is employee hand exposure to impact hazards.

What are impact-resistant gloves?

Impact-resistant gloves were designed to meet the needs of people who have exposures to hand impacts. These gloves protect fingers and knuckles when working with impact tools or performing tasks that could cause an impact injury. Generally, the outer shell of the glove has layered or raised rubbery material, known as Thermo-Plastic Rubber (TPR), designed to be placed at specific spots on the glove where impacts can naturally occur.

Industries that are most susceptible to impact hazards include oil and gas, drilling, mining, and manufacturing. These industries report over half of their injuries are finger and hand injuries caused by crushing, striking, pinching, and punctures.

Protection Needs

Conducting an effective risk assessment serves multiple purposes:

- it is a compliance requirement under OSHA;

- it helps identify real and potential hazards to which your employees are exposed;

- it allows for rating and prioritizing injury severity and frequency, which then allows your action items to eliminate or reduce those exposures to match the appropriate level of protection.

This last purpose is important. Depending on the hazard, it is possible to select an impact-resistant glove that under-protects or, in some cases, over-protects. Certainly, a glove that does not provide enough protection for the hazard has no value to your employees and no value in reducing exposures or injuries. But over-protection can also create additional problems.

When is it the wrong choice to select one type of PPE that offers “better” protection than one that offers “adequate” protection?

Related to impact gloves, too much protection for a specific task can be dangerous and expensive. Purchasing a higher-rated protective glove is more costly in price; generally, these higher-rated gloves are also thicker (to combat the higher level of impact exposures), which can create dexterity, grip, and tactile (cannot feel the tool or equipment) issues.

Selecting the appropriate glove, one that is matched and rated for the identified exposures, allows you to not overspend while providing appropriate protection levels. When the glove matches the hazard, an employee can properly handle the tools and equipment, reduce risk of injury from loss of dexterity and grip, and can work more efficiently (meaning more productively).

Impact Injury Costs

The costs associated with hand impact injuries can be staggering, far beyond monetary expenses. One crushing injury can exceed $140,000; each puncture or laceration can cost upwards of $50,000.1 Serious hand injuries can be considered “critical” injuries as the hand is necessary for performing life functions. A temporary or, worse, a permanent, loss of function can impact the employee’s ability to continue earning a living, cause additional financial hardship for his or her family, which increases stress and changes the person’s quality of life – perhaps for life!

One injury can be expensive. If the wrong PPE is selected, the risk of more frequent and severe injuries is real. The employer risks additional losses in community reputation, shareholder profits, loss of employee morale, attendance, and performance, higher workers’ compensation claim costs, and “on the radar” of regulatory agencies for special incident or complaint investigations, penalties, and fines.

As a supervisor or manager of an injured employee, you can also be at risk of losing your job, being demoted, or become a party to civil lawsuits or OSHA criminal investigations. That could all happen by being considered negligent in identifying risks, selecting appropriate PPE, and/or condoning or ignoring unsafe practices of your employees.

To help in your selection process, there is help available. If you are new to your role or just unsure on how to conduct an effective risk assessment, you can seek assistance from your workers’ compensation insurance carrier, other safety professionals within the company or within your industry, trade association assistance, and PPE manufacturer or distributor representatives. You do not have to travel this road alone and certainly you do not have to “settle” with the wrong or inferior selection of PPE. (You can check out our TRACK program, our no-cost consultation to support your evaluation and selection process).

PPE Limitations

You already know not to make your selection that could under- or over-protect. You must also remember that your PPE selection comes with limitations. Knowing those limitations and training your employees on them actually helps protect your employees.

You know there is no such thing as one chemical glove protecting the wearer from all chemicals. You know protective footwear only protects up to a 75-pound weight dropped from 18”, meaning it protects toes from manual material carrying and handling. It provides “limited” protection if you drop a 2-ton motor suspended from a crane on your foot.

The same is true with impact protection. These gloves are tested and rated up to a certain level or standard. Exceeding that level does not mean the gloves shouldn’t be worn; it does mean that the gloves may not provide protection above the rated levels. In such cases, you need to ensure you have engineered out the hazard as much as is possible at the source and have effective and safe procedures in place for employees to follow that reduce such risks. Proper training is necessary so employees performing tasks know where and how to position hands and when to remain clear.

Impact Ratings

In North America, impact gloves are governed by standards initiated by the American National Standards Institute (ANSI) with a work group from the International Safety Equipment Association (ISEA), updated in 2019 (ANSI/ISEA 138-2019).

Impact-resistant gloves that meet these new standards are measured by their ability to dissipate impact forces on knuckles and fingers. Since these impact risks can vary between industries and tasks, not all industries require the same level of protection or should select a single impact glove.2

PPE glove manufacturers that follow the ANSI standard must produce hand protection that offers degrees of impact resistance to reduce bruising, fractures, and pinched fingers for industries with impact energies.3 These degrees of resistance are tested and labeled based on rating levels that combine finger and knuckle protection.

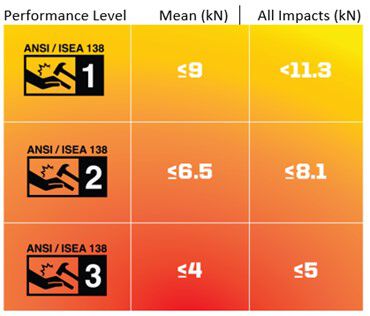

There are three designated categories or levels assigned to impact-resistance. These markings appear on gloves that have been tested, following the given ANSI standard. The figure below shows the three designated categories.

IMPACT-RESISTANT GLOVES

The overall impact performance level of the glove is determined by the lowest recorded performance level.

For example, if the fingers and thumb are rated as performance level 1, but the knuckles are performance level 2, then the entire glove is rated as performance level 1.

Test Method(s)

Which category is assigned to an impact glove is based on the outcome of the two tests – one for fingers and one for knuckles. The standard identifies certain locations on the glove to conduct the testing.4

The impact machine is set with a fixed 5.5-pound steel striker, providing a set force of energy to impact the specified glove locations on the fingers and on the knuckles. The machine measures the amount of that force penetrates the glove. The greater the resultant number, meaning greater force penetrated the glove, the less protective the glove.

Gloves that meet the prescribed standard are assigned one of three categories: Category 1 records the highest penetration of force and, therefore, is classified at the lowest protective level. So, the higher the glove category or rating up to level three, the better level of impact protection.5

Mechanix Wear® Impact Gloves

Mechanix Wear® manufactures gloves that have been tested and meet impact-resistance levels. These are not just for impact protection. We offer numerous styles and materials to give you protection levels for the various tasks you perform. Impact-resistance is included in many of our chemical, leather, hi-viz, and cut-resistance gloves. Gloves based on industry, such as oil and gas, tactical/military, coldwork and thermal, maintenance, and TAA-rated for government purchases, are a few of what is available to meet your specific needs.