Impact Resistant Gloves

ANSI / ISEA 138 - Impact Standard

ANSI / ISEA 138 is intended to protect hands where heavy tools and heavy equipment are at work. Construction, oil & gas, mining, automotive, and manufacturing industries will all benefit from this impact standard and its 3 designated performance levels of impact protection.

ANSI / ISEA 138 is the American National Standard for Performance & Classification of Impact-Resistant Work Gloves, and is intended to protect hands where heavy tools and heavy equipment are at work. Construction, oil & gas, mining, automotive, and manufacturing industries will all benefit from the new standard and its 3 designated performance levels of impact protection.

ANSI / ISEA 138 compliant impact-resistant gloves are measured by their ability to dissipate impact forces on the knuckles and fingers. Not all industries encounter the same impact risks, therefore not all industries require the same impact gloves.

ANSI / ISEA 138 will require manufacturers to produce hand protection with degrees of impact resistance to reduce bruising, fractures, breakage and pinched fingers in industries where impact energies are experienced.So how do the folks in the lab do it? When it comes to ANSI/ISEA 138 impact resistance, every focal point is measured for all-around performance testing.

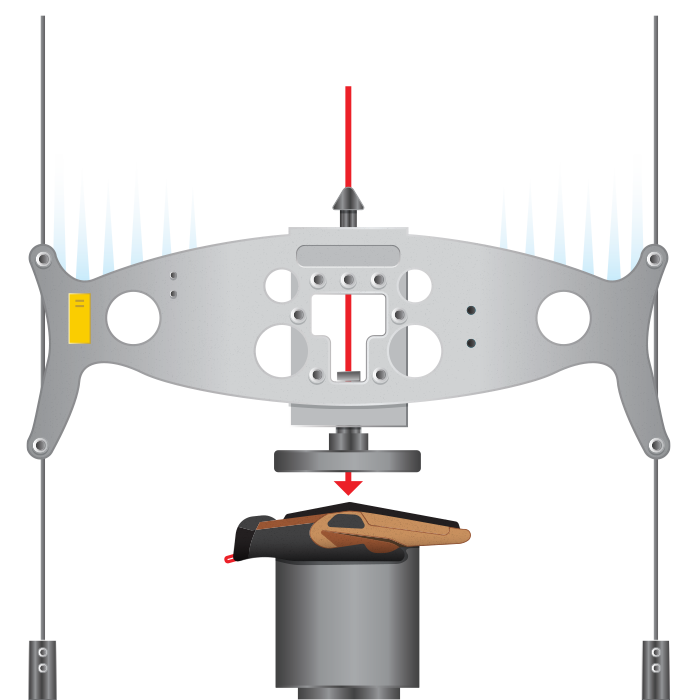

PREP FOR FINGER TEST

The index, ring finger and thumb impact sites are determined by measuring 25 mm ± 1.25 mm (0.98 in. ± 0.05 in.) from the fingertip down the middle of the finger. The pinky and middle finger impact sites are determined by measuring 50 mm ± 2.5 mm (1.97 in. ± 0.1 in.) from the fingertip down the middle of the finger.

PREP FOR KNUCKLE TEST

The impact sites for testing the knuckle are determined by gripping a bar between 1-1.5 inches in diameter and 4.72 inches in length. The most prominent point of each of the 4 knuckles is marked on the glove by 3 assessors and the triangle between the 3 marked points is centered on the testing anvil.

IMPACT MACHINE

HOW IT WORKS

The impact machine is prepared with a 5.5 pound steel striker and released along a vertical path with 5 ±.02 J of force onto the glove sample placed. The sample is placed on a test anvil attached through a force transducer for recorded measurement.

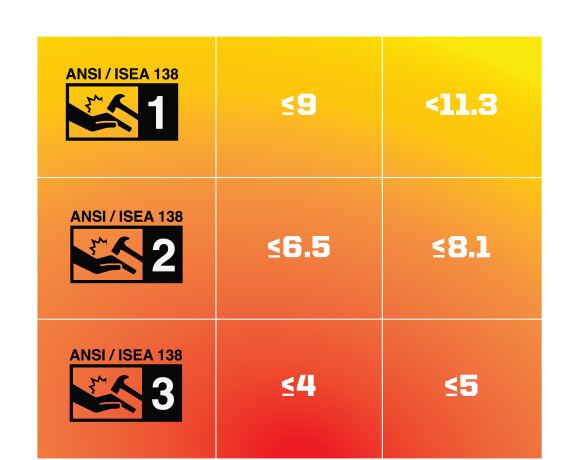

PERFORMANCE + CLASSIFICATION

IMPACT-RESISTANT GLOVES

The overall impact performance level of the glove is determined by the lowest recorded performance level. For example, if the fingers and thumb are rated as performance level 1, but the knuckles are performance level 2, then the entire glove is rated as performance level 1.